Additive Manufacturing: The New Era of Efficiency and Design Freedom

Nowadays, industries are looking for alternative manufacturing processes and workflow; additive manufacturing has been increasing across all types of industries as it can provide flexibility and efficiency.

Additive manufacturing adds great value to supply chains, and unlocks a broad spectrum of production applications 3D printing technology has become more affordable and industries have been able to bring additive manufacturing in-house to support their processes.

Industries that are Implementing Additive Manufacturing

Automotive Industry:

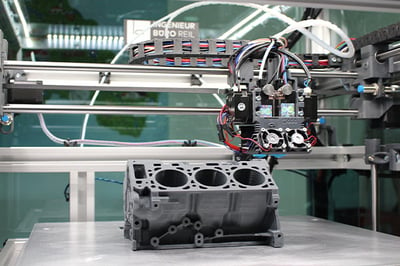

Additive manufacturing allows for automotive industries to have efficient solutions for metal-based 3D printing without being restricted to any forms. Engines, cast aluminium wheels, hubcaps, grilles, side air vents, door handles, and exhausts are 3D printed. Additive manufacturing has also allowed customers to design their own inner and outer components of the vehicle they are purchasing.

Aerospace Industry:

The aerospace industry has been an early adopter of 3D printing services; it has helped it evolve since the 1980s. Having high-precision and high-quality parts is important for the aerospace industry, and additive manufacturing aids this process. Jigs, gauges, fixtures, surrogates for training processes, interior components such as cockpit dashboards and door handles are 3D printed. Large-scale engine components are starting to be 3D printed, such as a titanium engine for Rolls Royce!

Medical Industry:

Personalized, small, and complex parts are needed for the medical industry. Medical technology uses additive manufacturing to produce digital models from x-rays, tomography scans or MRI scans and feed into a 3D printer. There are four core uses of 3D printing in the medical field associated with recent innovations, such as creating tissues and organoids, surgical tools, patient-specific surgical models, and custom-made prosthetics.

- Bioprinting: rather than printing using plastic or metal, bioprinters use a computer guided pipette to layer living cells on top of on another to create artificial tissue in laboratory.

- Surgical Instruments: sterile surgical instruments such as forceps, hemostats, scalpel handles and clamps can be produced using 3D printers.

- Custom made prosthetic such as prosthetic limbs

Energy Industry:

Additive manufacturing helps energy companies manufacture parts that meet today´s requirements for new and alternative energy. Worn components have been needed to be replaced and 3D printing allows for alternative and new components to be adapted to existing equipment. Spare parts printing supports energy industries in moving to digital supply chain addressing local supply, just-in-time inventory, obsolescence, and other supply chain opportunities.

Railway Industry:

Maintenance is one of the most common applications of 3D printing in the railway industry. The future of transportation is demanding new trends. As public transportation is enabling global sustainable living, additive manufacturing helps the railway industry adapt to this change. Additive manufacturing is helping bring obsolete spare parts back into the market with less fabrication time.

Manufacturing & Design

3D printing and additive manufacturing has been used for prototyping and R&D by many manufacturers, design companies and artists.

The technology has developed to move into mainstream manufacturing, and is developing rapidly to allow widespread adoption. Read our article about The Emergence of 3D Printing.

This presents many challenges but also many opportunities. Rileys Surface World can help with one of those key challenges in particular: Surface Finishing of 3D manufacturing parts

To read our full series of articles about 3D printing & additive manufacturing, check out the links below.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now