Riley Surface World unveils multiple surface finishing plant opportunities at O & S, Stuttgart, 2016

Riley Surface World will be exhibiting at O & S, the exhibition dedicated to electroplating and surface finishing in Stuttgart, Germany, May 31 – June 2, 2016, hall 7, stand F15.

The major theme of the stand will be opportunities for manufacturers or sub-contractors anywhere in the world to acquire complete, used process plants and associated machinery at greatly reduced prices in comparison to new capital equipment.

Riley will also be inviting offers from manufacturers to sell their surplus plant and machinery.

Major electroplating and powder coating lines available in Germany

The first opportunity concerns a large selection of electroplating machinery that has become available due to the closure of leading sub-contractor BKM Europe.

The equipment has been used for plating on plastics and metals.

Former clients of BKM include: Audi, BMW, Bosch-Siemens, DaimlerChrysler, Geberit,

Included in the inventory are two substantial copper/nickel/chrome lines; a 55 station line for plating on plastics and a 40 station line for plating on metals.

In addition, there is a demineralised water treatment plant, a reverse osmosis pure water plant and a filter press installation.

Large powder coating & painting facility, northern Germany

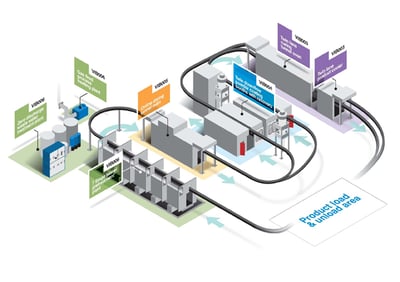

The next opportunity concerns a large Würster powder coating and painting facility formerly used by JCB Vibromax in northern Germany.

JCB Vibromax was a manufacturer of road rollers. Following the restructuring of its manufacturing operations, the powder coating and painting plant and the building in which it is housed, are now available as a going concern or for relocation.

Würster, which is also based in Germany, is one of the world’s leading producers of powder coating and painting plant and machinery

The facilitywas manufactured and installed in 2008. It consists of a pre-treatment line, drying and curing ovens, twin powder booths, waste water treatment plant, conveyor installation and Siemens control system.

Plasticraft aerospace-quality 12 station rack anodising/electroplating line

Triumph Structures, based in Farnborough, UK, manufacturers, repairs and refurbishes a wide range of aircraft components.

The anodising plant can easily be adapted for use with other surface treatment processes such as phosphating, nickel, zinc or cadmium plating, tartaric anodising,

It includes a motorised transporter system with full PLC controls.

Ancillary equipment includes chemical storage facilities, spray/bake room, drying oven and down-stroking presses for moulding thermoplastic materials.

Unique showcase for redundant plant and machinery

Riley Surface World is inviting companies that have redundant surface finishing plant and machinery available to take advantage of the exposure that the Riley showcase at O & S provides. It is a unique opportunity to display valuable assets before approximately 10,000 visitors from 100 countries at one of the world’s leading surface technology forums.

Over 1000 surface finishing machines in stock and online

Finally, visitors to the show will also have access to the Riley Surface World stock of over 1000 items of new and used machinery, covering all surface treatment and coating categories. This includes polishing and linishing, ovens and furnaces, process cooling, cleaning and degreasing, shot blasting and peening, dust and fume extraction and much more.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now