SNOL Custom Build Furnaces & Ovens

New

- Price [?]

- Please call on +44 (0) 1922 45 8000

- Guarantee

- 1 year manufacturer guarantee

- Availability:

- Available subject to build time

- Condition

- Brand New

- Stock No

- NEW079

- Manufacturer

- SNOL

- Condition

- Brand New

- Delivery Your delivery options

Description

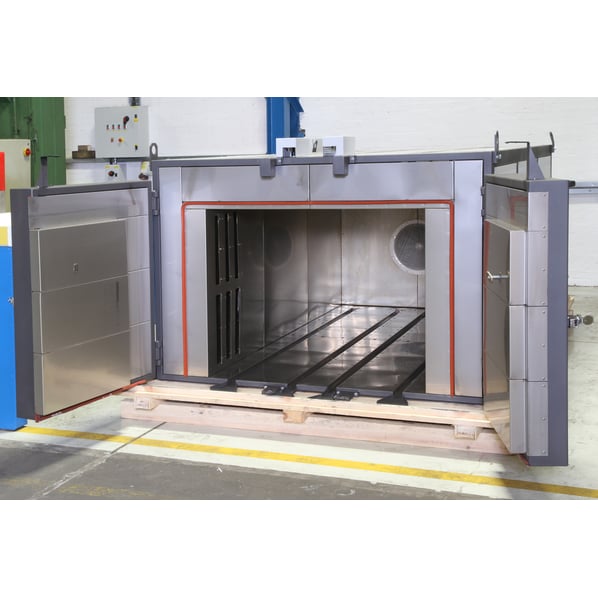

Custom Build Furnaces & Ovens

The combination of Riley's and SNOL's experience has unlocked heat treatment solutions for a wide range of UK manufacturers. The temperature range includes 200°C to 750°C for ovens & up to 1600°C for furnaces, the possibilities are endless for your perfect heat treatment.

Outlined below are a range of custom build projects that have delivered to specification at excellent value. Please contact us if you would like to discuss a project.

SNOL - a leading thermal engineering manufacturer

SNOL is one of the leading industrial oven and furnace manufacturers in the world. The company is based in Lithuania with subsidiaries in Germany and Ukraine. Founded in 1960 SNOL and is part of the Baltic State's largest metal processing group, employing over 700 people. 90% of production is exported from Lithuania into 40 countries in Europe and worldwide.

SNOL is one of the leading industrial oven and furnace manufacturers in the world. The company is based in Lithuania with subsidiaries in Germany and Ukraine. Founded in 1960 SNOL and is part of the Baltic State's largest metal processing group, employing over 700 people. 90% of production is exported from Lithuania into 40 countries in Europe and worldwide.

Riley Surface World and SNOL is a unique partnership. It combines Europe’s finest industrial and laboratory oven manufacturer with a UK company renowned for its high levels of industry knowledge, service and technical support.

The combination of Riley's industry knowledge and SNOL's design and manufacturing capabilities have delivered successful oven and furnace projects that meet the customer's requirements up to AMS Aerospace standards.

650°C 12,800 Litre Bogie Hearth Oven

A detailed research and analysis process led to the specification of a high quality custom built oven to be manufactured by RSW’s partner SNOL based in Lithuania. SNOL has a proven history of manufacturing heat treatment ovens to this high specification.

- 12,800 Litre capacity

- 620°C operating temperature

- AMS2750E Class 4 Standard

- ± 5°C temperature uniformity

- Electric heating with minimum kW rating possible

- Forced air circulation including controlled cool down

- Vertical uprising front opening door

- Powered trolley/bogie, 6000kg product load

225°C 1.2m x 0.95m x 2.3m Electric Oven Custom Built for Tier 1 Automotive Manufacturer for Coil Heat Treatment

Having seen the quality of SNOL ovens a regular customer, one of the oldest names in British engineering, chose Riley Surface World to build a custom sized electric oven for one of their automotive production facilities.

- 1.2m x 0.95m x 2.3m internal size

- 225°C operating temperature

- 4x floor rails for custom trolley

- Custom door and control panel locks

250°C 2m x 2m x 2m (8000 litre) Electric Oven - Performance Automotive with High Tolerances required

The flexibility of Riley Surface World's supplier roster ensures we can find a solution for you. In this case the customer needed an oven that was close in specification to our Romer 225°C 8000 litre ovens but during the specification process it was clear that higher tolerances and control mechanisms were required than fitted as standard on the Romer ovens. SNOL were able to provide an oven on specification as follows.

- 2m x 2m x 2m internal size

- Max 250°C operating temperature; process at 150°C

- Tightly controller Ramp Up & Ramp Down balanced for material mass and configuration

- Nanodac Programmable Controller & Data Logger

- Flying Lead Thermocouples for monitoring each batch

4x 200°C 80 litre Electric Ovens for Medical Ceramics Manufacturer

These 4 ovens mounted with one control panel provide several benefits beyond the reduced footprint. For this customer parts could be batched by cure time and left in the chambers without having to repeatedly open one door. This improved quality and safety.

- 4 chambers

- Up to 200°C operating temperature

- Omron E5CC-T programmable controllers

- Eurotherm Nanodac temperature recorder

- Individual fan speed controller for each chamber

- individual delay start time for each chamber

350°C 1408 Litre Stainless Steel Electric Oven

One the UK's best known aerospace sub contract companies has specified and purchased a custom build electric oven.

- 1.6m x 0.8m x 1.1m internal size (wxdxh)

- 350°C operating temperature

- +/- 5°C uniformity

250°C 216 Litre Electric Oven with Lift up Door

A innovating company providing post processing for additive manufacturing (3D Printing) needed an oven they can automate with a conveyor system and robotics for their ongoing product development. Rileys worked in partnership to design an oven with the correct ergonomics and features to keep this customer at the forefront of their industry. Watch the Video

- 0.6m x 0.6m x 0.6m internal size (wxdxh)

- 250°C operating temperature

- Lift Up Door

- Omron E5CC Controller

250°C 1500 Litre Electric Oven with fully Welded Chamber

A leading Nickel Zinc battery manufacturer with a specialist background in submarine technology needed an oven to perform at high accuracy. Given the processes used this oven needed to be gas tight with no fumes escaping into their facility during treatment. SNOL and Rileys designed them an oven to achieve this with a welded chamber, double silicon seals and connection to an in house extraction system.

- 1m x 10m x 1.5m internal size (wxdxh)

- 250°C operating temperature

- Stainless Steel Chamber

- Double Silicon Seal

- Floor Rails

- Chimney connected to in-factory exhaust system

- Omron E5CC programmable controller

250°C 1800 Litre Fully Stainless Steel Cleaning Room Oven

Designed for a regular customer with many years experience delivering precision cleaning services for semiconductor equipment this oven was placed in a hi-specification cleaning room. Fully Stainless Steel with and enclosed fan the features of this oven allow it to be placed in a controlled cleaning room and maintain the environmental conditions.

- 1200mm x 750mm x 2050mm internal size (wxdxh)

- 250°C operating temperature

- Outside casing in stainless steel sheets and frame from stainless steel tubes

- Ventilation motor on the top

- External adjustable air inlet and outlet

- Controller Eurotherm 3208

![]() Print / Download SNOL Custom Build Furnaces & Ovens Datasheet

Print / Download SNOL Custom Build Furnaces & Ovens Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now