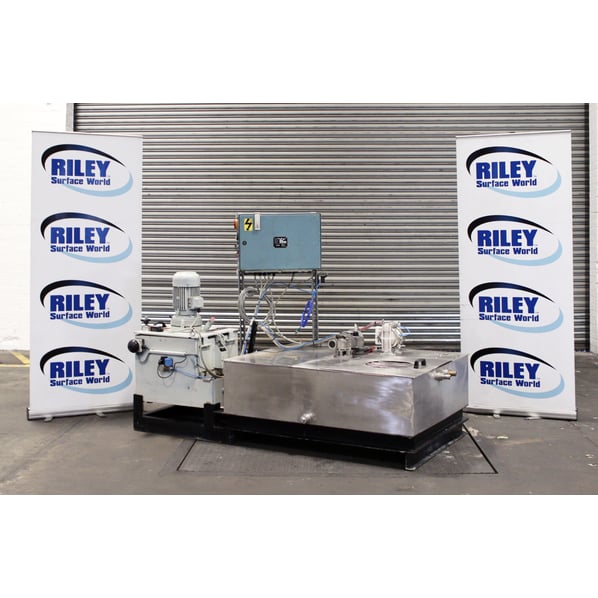

Acton Waste Water Sludge Separation / Treatment Facility with Centrifuge.

- Stock No

- VB2204

- Manufacturer

- Acton

- Model

- A 800 Batch Centrifuge

- Year of Manufacture

- 2016

- Serial

- 2511-0816

- Condition

- Good Condition, Seen powered at RSW

- Capacity

- Tank ~ 280L : Centrifuge ~ 100L

- Type

- High Speed Sludge Centrifugal Separator.

- Other Info

- 280L Stainless Steel Holding Mixing Tank

- Location

- Our Central Warehouse, Aldridge, UK

- Weight (kgs)

- 422

- External Dimensions (WxDxH mm) [?]

- 1130 x 2120 x 1100

- Delivery Your delivery options

Description

Stainless steel settlement tank and centrifuge for sludge de-watering, ideal for mass vibratory surface finishing machines & installations. The process water is recycled through the system filtering out the sludge/sediment and impurities, recycling/returning the clean water to the process.

Contaminated water from a vibratory surface finishing process flows into the stainless steel settlement tank via a mesh filter and is gently stirred in the tank. This pushes the larger particles to outside of the unit and a centrally mounted diaphragm pump, pumps the liquid into the base of the centrifuge unit. There is a secondary mesh filter to gather larger particles and then the force of the centrifuge spins the liquid around and up towards the top outlet, which is centrally sited. The larger particles and sediment sticks to the outer centrifuge wall cover, cleaned fluid is forced through the outlet pipe back into the system for re-use. Periodic swapping and cleaning of the lining keeps the downtime to a minimum.

Features (Main Tank)

- Stainless steel settlement tank.

- Approx. size 1050mm x 1330mm x 350mm, 280 Litres

- Twin inlets. (Capable of servicing two lines or process machines).

- Inlet mesh strainer.

- Inlet hoses Ø30mm approx.

- Slow rotation stirring/mixing paddle.

- Air Diaphragm pump. (Wilden 01-3181-20)

- Bottom drain plug.

Features (Centrifuge)

- Centrifuge approx. Ø390mm 100 Litres.

- Up to 14 litres (19kg) of sludge.

- Spare sludge collection drum.

- Two brakes, one electrical and one mechanical.

- Electrical control panel for centrifuge and settlement tank.

- 3.2kW 400 Volt, 3 phase, 8 Amp supply.

- Spin speed 2800 rev/min.

- Two sediment collection linings.

This model's easy-to-handle, robust construction with manual discharge and emptying of the mud baskets. In one cycle, up to 14 litres (19kg) of sludge can be separated. Two removable sludge baskets are provided.

It won’t work without process water

Water and compounds are essential for vibratory mass finishing. During the process the used water becomes polluted with fines from media, metal fines, oils and grease from the workpieces.

Therefore, the water has to be cleaned. If the processed water goes to the drain it has to be cleaned more thoroughly (via flocculation) than would be necessary with centrifugal recycling. The idea would be to constantly recycle the effluent from mass finishing operation. It saves not only water (up to 98 %), but also compounds (up to 90 %).

Furthermore, the user does not need permission for the discharge to the sewage system from the Water Authorities, thus saving disposal costs (approx. 50 % less than with a flocculation process alone).

For most mass finishing applications, recycling is possible. Occasionally however there are applications where recycling is not advisable: For example, pickling with acid or using several compounds in one process or high precision cleaning. In such applications, a “single pass” system including flocculation of the waste water would transfer directly to drain is the most simple and safe process.

![]() Print / Download Acton Waste Water Sludge Separation / Treatment Facility with Centrifuge. Datasheet

Print / Download Acton Waste Water Sludge Separation / Treatment Facility with Centrifuge. Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now