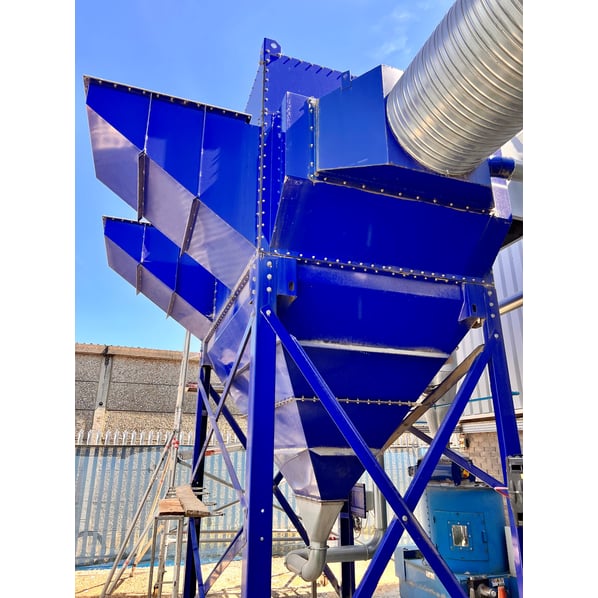

Camfil Farr GS24 Dust Extraction Unit

- Stock No

- ED2124

- Manufacturer

- Camfil Farr

- Model

- GS24 Venting Unit

- Year of Manufacture

- 12/2013

- Serial

- 301011

- Condition

- From a working environment, Excellent Condition, Current Model

- Approx Duty CFM / M³/Hr

- 21,375CFM // 36,300M3/Hr

- Filter Area ft² / m²

- 8125ft2 // 755M2

- Other Info

- Camfill Gold Series Control System

- Location

- Our Central Warehouse, Aldridge, UK

- External Dimensions (WxDxH mm) [?]

- 4500 x 4700 x 5240

- Delivery Your delivery options

Description

Gold Series dust collectors offer high dust processing capacity with low pressure drop, delivering maximum airflow and power for a given footprint.These are top-rated dust collection systems incorporating proven technology that has delivered successful performance in the field for over 25 years. These collectors are designed to handle a wide range of toxic and combustible dust and fumes, including fine, fibrous and heavy dust loads.

The baffle configuration works to drop out large particles before they reach the filters. This helps to extend the filter’s lifespan, reduce the need for frequent change-outs and reduce the total cost of ownership.

Key Features

- Engineered to protect workers from occupational exposure and combustible dust explosions. Delivers the maximum CFM of clean factory air.

- Safely contains combustible dusts. Gold Series collectors with explosion protection systems exceed NFPA and ATEX standards.

- Crossflow technology creates a uniform airflow so filters cartridges last longer

- Gold Cone filter cartridges are positioned vertically for superior release of high-loading dust with pulse-cleaning. They deliver maximum airflow and efficiency.

Modular Design

It’s easy to customize Gold Series industrial dust collectors for your specific work environment. Individual modules contain four filters and accommodate airflows up to 6,000 CFM each, providing a near-limitless variety of configurations and airflow capabilities. You get fast delivery of an industrial dust collection system that is just right for your application and space. It's ideal for collecting dust from the manufacturing and processing of dry bulk powder

Vertical Filters Cartridges

Gold Cone™ filter cartridges are positioned vertically in the dust collectors. This means dust won't fall onto the filters below on its way to the hopper. With each pulse of compressed air, the dust and debris is ejected out of the filter cartridges, and gravity pulls it down into the hopper.

Gold cone filter part number 325325-003

How do Dust Extractors Work?

Dust collection systems work in a variety of different ways but all have general principles in common. They draw process dust and particulates from the air through a filter that first captures and separates the matter, and then discharges decontaminated air back into the workplace or environment.

Dust extractors are used in many different and varied industries and so different demands are made of them; however all have common components such as a blower (or fan), dust filter, filter cleaning system, dust container and dust removal system.

Five common types of dust collection equipment are fabric filter baghouses, inertial separators (like mechanical cyclones), cartridge collectors, wet scrubbers, and electrostatic precipitators.

Importance of Explosion Panels in a Dust Extractor

As extraction systems suck in air in concentrated volumes, the risk of explosive dust igniting is greater; therefore precautions are required to control the risk. A dust extractor with explosion panels installed will have these panels located in the areas where the dust is most likely to combust, controlling the explosion so it ignites in the area that has been constructed to withstand the impact without damaging the extractor itself.

Factors to Consider for Your Next Dust Extractor

When implementing the safety measures to ensure minimal risk to your workers, the factors to consider when purchasing your extraction unit/system are:

- Dust Source - Does the process that produces dust occur in an enclosed or open area?

- Capacity - Does the extractor have a large enough filter area required to handle the volume of dust?

- Type of Dust – Do you need an extractor capable of handling dust at risk of self-igniting?

- Maintenance – Would a self-cleaning extractor with an automatic shaker cycle be more suitable for you?

For further guidance, find out how to carry out your own COSHH (Control of Substances Hazardous to Health) risk assessment at the HSE website to help calculate your requirements.

Importance of Dust Extractors

Dust in the workplace can affect product quality and employee´s health. Having a dust-free environment is essential to the health and safety of the workforce. Not only does it affect the health of employees but the dust covers the equipment affecting production processes and quality of the products.

Capturing the dust at the source prevents it from spreading, done by using a dust extractor system to facilitate the important housekeeping to avoid it from accumulating.

What are Cartridge Dust Collectors?

Cartridge Dust Collectors a type of filter unit which is predominantly used in environments where space is at a premium. They can often maintain airflows which remain comparable to larger baghouse units.

Cartridge units provide larger fabric filter areas into a smaller place, use less filters and can be changed from the outside of the extractor, rather than having to access the unit internally, thus reducing filter replacement times and less environmental contamination issues for maintenance staff.

They are ideal for commercial and industrial environments, whose processes produce very fine-to- moderate dust-like powders, metalworking, woodworking, fume collection, thermal spraying, among other processes.

![]() Print / Download Camfil Farr GS24 Dust Extraction Unit Datasheet

Print / Download Camfil Farr GS24 Dust Extraction Unit Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now