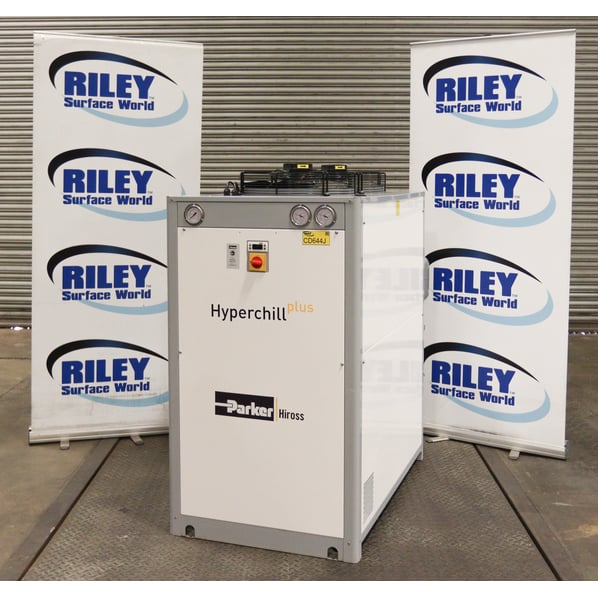

Parker Hiross Hyperchill Plus ICEP024 Industrial Chiller

- Stock No

- CD644J

- Manufacturer

- Parker Hiross

- Model

- ICEPO24

- Year of Manufacture

- 2018

- Serial

- 399691810001

- Condition

- Refurbished by RSW, Excellent Condition, Current Model, Seen powered at RSW

- Ave. cooling capacity

- 24kW

- Other Info

- Load tested by Evolution Cooling Ltd

- Location

- Our Central Warehouse, Aldridge, UK

- Weight (kgs)

- 230

- External Dimensions (WxDxH mm) [?]

- 760 x 1450 x 1420

- Delivery Your delivery options

Description

Parker Hiross Hyperchill plus ICEP024 chiller ensures accurate control of process water temperature, designed for safe and reliable operation in the most varied working conditions thanks to its modern technical innovations.

Extremely compact and easy to use, Hyperchill ensures an accurate control of water temperature.

Each model is designed for safe and reliable operation in the most varied working conditions, thanks to

the modern technical solutions used and the availability of a wide range of accessories and options.

Each individual Hyperchill unit is extensively tested to guarantee efficient operation and reliability in all working conditions.

Process Cooling Applications:

- Laser technology

- Extruders

- Surface processing

- Welding engineering

- Blow mould machines

- Printing systems

- Coating systems

- Chemical and pharmaceutical

- Plastics processing

- Thermoform machines

- Plasma coating

- Medical Imaging

- Food & beverage industry

- Injection moulding

- Cutting machine tools

- Electroplating baths

- Bioenergy

- Compressed air

Product Features:

- Hydraulic circuit: water tank, immersed evaporator, pump with bypass provide a compact and easy to install solution.

- Electronic controllers with proprietary software provide access to all the parameters of the units and allow special management for any specific need.

- Available with remote monitoring.

- Completely configurable with many options and kits to fit many industrial applications needs.

- Condenser filters.

- Independent condensing plenum.

- Full access and easy service design high reliability and back-up eliminate downtime.

- Large water tank allows minimum compressor cycling and precise temperature control.

- Maximum ambient temperature up to 48°C lowest energy consumption in the market.

- Use of compliant scroll compressors.

- Expansion vessel with interchangeable membrane.

Benefits of the Hyperchill Plus Range

- Water and refrigerant manometers permit full control of the working conditions.

- Microprocessors allow complete control of the unit parameters.

- Proprietary software allows a wide range of programming and remote monitoring options.

- Compliant scroll compressors with less moving parts for excellent efficiency, high reliability and low noise levels.

- Air cooled with axial fans suitable for outdoor installation (no need for protection).

- Mesh filter condenser protection from dirt and contamination, reduces maintenance costs and the risk of downtime.

- Evaporator located inside the water tank, reducing the overall dimensions, increases the efficiency and improves temperature control.

- Water by-pass protects the pump and supplies constant flow to the evaporator avoiding alarms and freezing.

- Water tank generously dimensioned to guarantee high reliability and improved temperature control.

- Accepts incoming water temperatures of up to 30°C.

- Can produce differences between incoming and outgoing water of 15°C.

- Able to operate with ambient temperatures of 48°C.

- Compliant scroll compressor, giving greater efficiency, longevity and quieter operation.

- Twin axial roof mounted fans.

- Includes microprocessor control to allow for greater control of the conditions necessary for your process.

- Dimensions: 760mm x 1450mm x 1420mm.

- Weight: 270kg.

- Refrigerant R407C.

Principles of Refrigeration

A refrigerant cooling system is a closed loop system which contains a refrigerant gas. This gas is compressed and pressurised through a compressor and cooled through a heat exchanger and fan arrangement to produce a high pressure, liquid refrigerant.

This liquid refrigerant then passes through a hot gas expansion unit, where it is allowed to expand and ‘evaporate’ back into a low pressure gaseous refrigerant. The change of state from a liquid to a gas draws heat from the surrounding area. This is normally carried out within a high conductivity heat exchanger allowing it to draw and remove heat from the liquid or air that needs cooling.

The gas then re-enters the compressor and the process is repeated. As such electrical energy put into the compressor pump can be used to produce a cooling or chilling effect.

Key components;

- Compressor: Produces high pressure gas

- Condenser: Liquefies and cools the refrigerant by passing it through a heat exchanger

- Expansion valve: Controls the flow of the liquid refrigerant to the evaporator.

- Evaporator: Allows the refrigerant to turn back into a gas, whilst using the drop in temperature to remove heat from the external processes which require cooling

![]() Print / Download Parker Hiross Hyperchill Plus ICEP024 Industrial Chiller Datasheet

Print / Download Parker Hiross Hyperchill Plus ICEP024 Industrial Chiller Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now