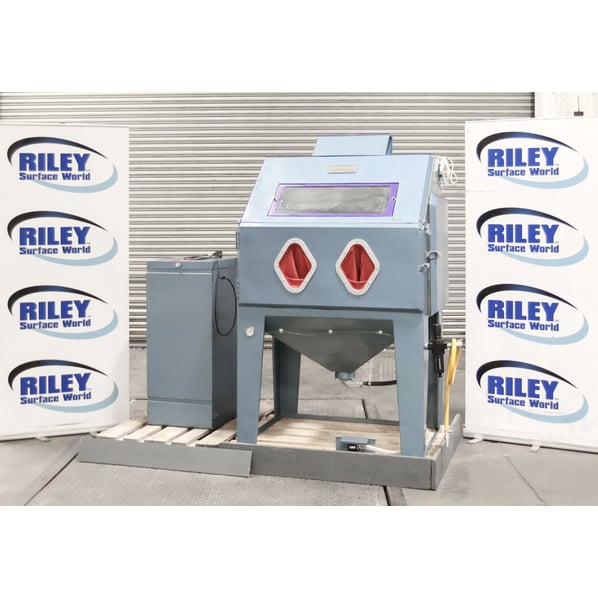

Guyson International Euroblast 6 SF Suction Fed Blasting Cabinet

- Stock No

- SD1031

- Manufacturer

- Guyson International

- Model

- DBH6/40 SF

- Serial

- 67066

- Condition

- From a working environment, Good Condition, Seen powered at RSW

- Work Envelope (WxDxH mm) [?]

- 975 x 700 x 600mm

- Work Handling Method

- Manual with 3 Access Doors

- Other Info

- Very Little Used

- Location

- Our Central Warehouse, Aldridge, UK

- Weight (kgs)

- 220

- External Dimensions (WxDxH mm) [?]

- 1100 x 900 x 1850

- Delivery Your delivery options

Description

A second hand popular Guyson Model Euro 6 suction venturi feed blast cabinet which has a universal appeal for all those medium sized engineering blast and cleaning jobs.

This shot blasting equipment offers a faster alternative to labour intensive operations such as hand deburring, scraping and wire brushing, chemical cleaning, acid etching or dipping, liquid honing, knife trimming, sanding, grinding and many others.

Suitable for cleaning without dimensional change, the dry blast techniques pioneered by Guyson (for even complicated shapes and sensitive materials) can be efficiently cleaned without substrate erosion or dimensional change. Ideal for the precision cleaning of moulds, dies and tools without damage to delicate surfaces.

Typical Uses of the Suction Feed System Include:

Cosmetic Finishing

Increasingly, cosmetic finishes can be the competitive edge that makes your product more attractive to the consumer. Whether you are addressing minor surface imperfections.

Deburring

Blast finishing can speedily remove lightly attached burrs from complex machined components and can be more effective than hand or machine deburring in areas with poor accessibility. Non-abrasive deburring media leave even fragile materials untouched.

Deflashing

Beadblasting can be used to rapidly and thoroughly deflash resin-moulded or die-cast components. Brittle flash can be cleanly removed from intricate components without altering adjacent surfaces by precise selective impact treatment.

Descaling

Use bead or grit blasting to quickly remove heat scale, surface discoloration, oxides, rust, weld scale or corrosion. Restore a component's looks and remove surface problems that interfere with painting, plating, coating, drawing and other processes.

Maintenance Clean, Re-manufacture, Refurbish

Guyson blast cabinets are successfully used in maintenance workshops, repair shops, service centres, garages and military depots on a varied component mix. They can eliminate laborious hand work, chemical cleaning and environmental issues from the workshop, and they are ideal for automotive core re-manufacture operations and refurbishing cutting tools, TCT and diamond tipped routers, saw blades, drills etc.

Surface Etching

Improved surface preparation or 'keying' of component surfaces can be achieved using Guyson blast equipment. Fine media blasting in one of our blast systems delivers very real improvements in adhesion for performance critical components such as medical implants when they are etched prior to ceramic or PVD/CVD coating.

Features

- Internal dimensions of 975mm x 700mm x 600mm

- Front access, both doors open - 950mm x 775mm

- R/H side access door - 530mm x 600mm

- Twin gauntlets.

- Air pressure regulator

- Fixed gun holster

- Front viewing window

- Internal lighting

- Blast Gun with 6mm nozzle

Includes Separate E41 DC Dust Filter

- sn-A17746

- 240V

- 500mm x 600mm x 1050mm

- 52kg

- 4 filter bags

- Manual shaker

Benefits of Suction Blast Cabinet

- Lower initial cost: a suction blast cabinet costs less than a pressure blast cabinet

- Lower operating costs: blast media is being supplied by a suction action rather than being fed with pressure, the media will leave the blast nozzle at a lighter pressure and speed.

- Lower air volume requirements: needs less air to function compared to a pressure fed cabinet.

Features to Consider for a Blasting Cabinet

- Cubic Force per Minute (CFM) - The power the air/water/media can be shot at.

- Dust Collection - For blasting for prolonged times lengths or dust-producing materials the dust would need to be controlled.

- Cabinet Construction - All cabinets need to be sturdy but for high-pressure shot blasting the construction needs to be secure.

- Type of Cabinet - Options include suction, pressure & water blast cabinets.

- Functional Design & View - Would the operation be able to use the cabinet and see through the window?

- Media - What purpose do you need to shot blast as different media can achieve different finishes.

- Accessories for Blast Cabinet - Is the cabinet sellf contained or does it required additional control, extraction and cyclone units.

![]() Print / Download Guyson International Euroblast 6 SF Suction Fed Blasting Cabinet Datasheet

Print / Download Guyson International Euroblast 6 SF Suction Fed Blasting Cabinet Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now