Quality Composite Manufacturing Needs Quality Machinery

Composite Integration uses their expertise to give customers complete control over the entire composites process. From small-scale production to large-scale R&D challenges, their CiJect range of machines gives customers the power to consistently produce high-quality parts more efficiently, with less waste.

Some of the core problems in high performance & volume industries such as aerospace, marine and wind face handling composites is repeatable, measurable quality in the critical steps of mixing, handling and delivering composite resins.

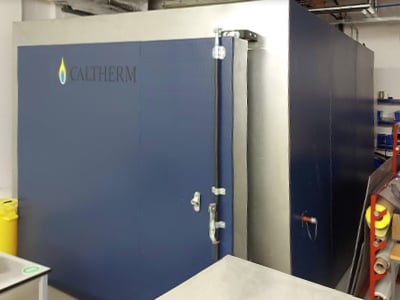

To trial and research the end product, a cured composite component for the kind of customer on Composite Integrations roster, you need to replicate the production environment. That’s where Riley Surface World has delivered, with a very high specification industrial oven just like the ones found in the most demanding factories – a ± 3°C AMS2750 Caltherm 250°C.

Composite Curing Oven - Repeatable and Quality Composite Production

As manufacturing technology evolves for higher volume and performance industries, it inevitably comes up against barriers to succeed. Composite Integration is one of the innovators in composite manufacturing, their pioneering spirit pushing the boundaries of what’s possible to achieve ground-breaking results.

The process can be complex, but Composite Integrations clear and simple to use machinery for mixing two-part composite resins and injecting them into moulds has made one of the fundamental steps of composite manufacturing easy. Their reliable machines easily achieve the difficult task of consistently mixing resin blends at the right temperature and viscosity – especially when you need to measure, record and repeat processes to ensure quality control.

Composite Integration is a composite supplier happy to share their knowledge and expertise in resin transfer moulding (RTM) and the direct infusion process with those manufacturing composites for the first time or looking for advice. Providing the right equipment and expertise to produce and refine your process for an industry that demands quality.

How Did Riley Surface World Help Composite Integration?

Riley Surface World finds new homes for unused industrial machinery. Sometimes, that involves buying and storing machinery. Sometimes, what’s on offer is so good and so well timed that the machine can go straight from its old home to the new.

That’s exactly what happened with the Caltherm 250°C Composite Curing Oven Composite Integration purchased.

Formerly an R&D machine at Cardiff University, this oven was in excellent condition from a top OEM and was brimming with quality features. It was built and calibrated to AMS2750D “Class 2” (±3°C) with full programming, recording and logging equipment for traceability. The oven had a great chamber size for composites and moulds of 2m x 3m x 2m.

Even better was the price, especially when compared to a brand-new equivalent, further reduced by Riley Surface World moving the oven directly between old and new locations.

Then of course the availability, no lead time & no waiting. It’s no wonder Composite Integration saw the potential to add value to their business and quickly secured the oven.And what did Composite Integration have to say about working with Riley Surface World?

“Lovely people to deal with at all points - friendly, professional and precise...”Tim Searle, Composite Integrations R&D Director (and our main point of contact)

What is the Oven Used for Now?

The specification of the Caltherm 250°C Composite Curing Oven provides huge flexibility. Composite Integration has a strong R&D background and now have an oven in-house to help them deliver their research in the Aerospace and Wind sectors producing highly specialised and often lightweight parts that contribute to a chain of developments for their customers.

Additionally, they can now prove their products and processes deliver for quality driven manufacturers by running product trials to the standard their potential and current customers work too.

Are You Looking to Invest in Composite Ovens?

Riley Surface World’s range of used Industrial ovens are often adaptable to the needs of the composite industry, many being sourced from composite manufacturers themselves. With immediate availability and prices that enable fast returns on investment, our catalogue is full of options.

To complement our used range, our brand-new range of Romer Composite Ovens have a growing roster of manufacturers curing composite components. Have you considered opting for a new one for your next oven?

Our new range of machinery provides you with the balance between high-specification machinery for great value; see for yourself the standard models and custom options we can offer you at New Ovens & Furnaces.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now