Quick Read: Flat Bed Deburring Introduction

A machine we frequently have in stock at our warehouse, flat part deburring machines are key to finishing metal components of a flat shape/form. The go-to for surface finishing, edge rounding, de-slagging, grinding and preparing for coating of flat metal components, the configuration of these machines can be adapted to suit the function.

Why is Deburring Needed for Flat Components?

During the manufacturing of metal components, a variety of processes are used that frequently leave small metal fragments & burrs on the components. If not corrected it would hinder the functionality and quality of the parts.

Processes that require deburring include:

- Graining

- Laser cutting

- Plasma cutting

- Water jet cutting

- Oxy-fuel cutting

- Punching

- Fine blanking

- Sheet metal work

- Perforators

- Plate cutting

Used in industries such as automobile to aerospace, flat part deburring is often used to finish components for clutches, compressor & valve plate brakes, and Hydraulic pumps.

How Does Flat Component Deburring Work?

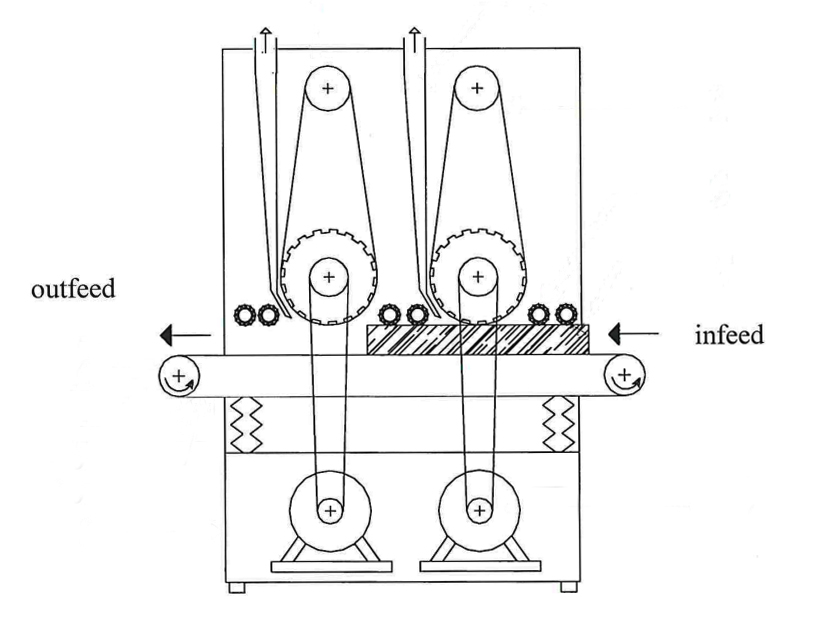

The simple explanation of flat bed deburring machines is that the parts are placed on a conveyor belt and moved through the machine whilst encountering some abrasive belt & brush heads when inside.

The abrasive belts are coated in different sized grit to remove the burr. Belts with smaller grit are more suitable for softer metal alloys while rougher belt grit is best for harder metals like steel.

Belt Set Up

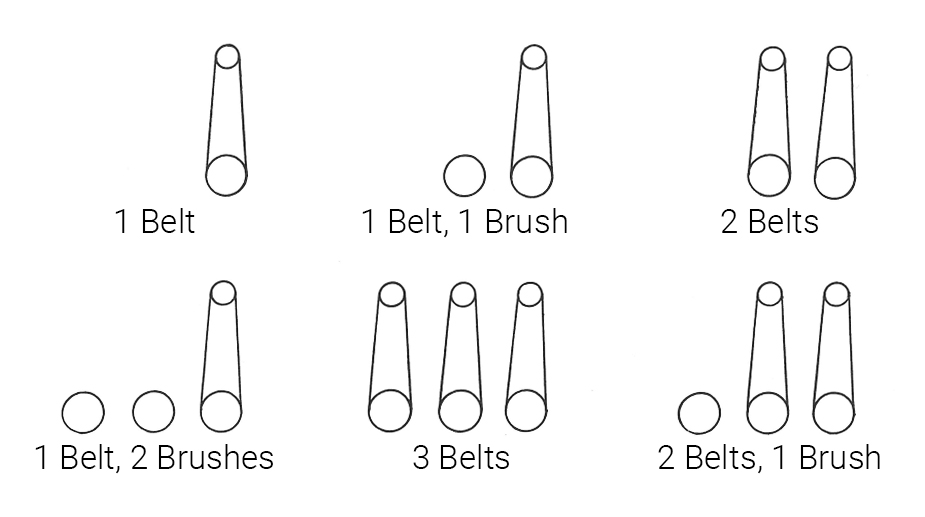

The setup of the grinders inside can be one, two or multiple belts like in the image above. By adding brushes to the process, additional finishes are available such as rounding the edges. Depending on the metal and size, the user is able to arrange the belts and brushes in the order that suits the component.

An example of why someone may want a belt-only lineup is that they want to finish the components with a uniform lined texture. Now recognised as a professional quality finish, this finish is frequently used in the aerospace and defence industries.

In a setup with brushes, the rotation of the brushes contrasts with the belts preventing a lined texture. Also, brushes have the advantage of being able to round the edges as part of removing sharp burr from the components. For a thorough deburr of the edges, we recommend a setup that includes two brushes but in opposite directions (clockwise and anti-clockwise) to reach all the edges of the component.

Rotary Deburring

The design of flatbed deburring machines is not limited to linear belts and brushes. There is a rotary alternative that uses solely brushes but instead of a long brush that goes all the way across the processing area, smaller brushes are fitted to a central spinning spindle. The smaller brushes vary between clockwise and anti-clockwise directions all while the spindle rotates and moves over the components.

This method is another option for metal finishers to consider when deciding on the most suitable deburring method for them.

Summary

The process of flat part deburring is a simple and effective solution for many businesses. Critical for metal finishing flat components, the process of just removing burrs has many benefits for the final finish and this method is just one of them.

To find more about other deburring techniques, check out our blogs below.

- Deburring: Smooth Out Your Metal for Perfect Functionality

- Deburring Machines – What are Your Choices?

- What is Barrel Tumbling Process?

- The Method of Vibratory Finishing

Weber 4 Head Flat Belt Grinder / Sander with Built in Coolant and Filter System

A Weber 4 head flat belt sander with built in coolant and filter system. Two driven grinding/sanding belts plus two driven brushes, with a variable speed work conveying belt and power driven height adjustment.

- Stock No

- PB1156

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Weber NLC-2/2-300

- Year of Manufacture

- 1998

- R.P.M.

- 3000

- Hp/Kw

- 33kW // 44Hp

- Other Info

- Conveyor Belt Width 300mm

- Condition

- Good Condition

Grindingmaster MCSB / B 600

This pre owned Ellesco Grindingmaster is a premier industrial metal working multi finishing 600mm wide belt dry working machine.

- Stock No

- PB1170

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Grindingmaster MCSB / B 600

- Hp/Kw

- 15 // 11

- Other Info

- 600mm wide belt

- Condition

- From a working environment, Seen powered at RSW

- Sold As Seen Price [?]

- £ 6,450 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Lissmac SMD123RE Wide Belt Graining / Counter Rotating 4 Brush Deburring Machine with Wet NonFlam Extractor

The LISSMAC ECOline grinding machine is a versatile machine that is designed to machine sheet materials or components that require either, deburring, edge rounding, surface finishing, or oxide/slag removal following a previous operation or production treatment. Waste dust is controlled by the matched, ESTA wet ATEX collector.

- Stock No

- PC1186J

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Lissmac SMD123RE

- Year of Manufacture

- 2017

- R.P.M.

- Various (see details below)

- Hp/Kw

- Power Input 28.5kVA

- Other Info

- Total Coverage, Belt + Rotating Brushes.

- Condition

- Seen working by RSW, Excellent Condition, Current Model

- Refurbished Price [?]

- £ 45,000 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Birkett Cutmaster Through Feed Horizontal Belt Linishing and Sanding Machine

This Birkett Cutmaster 900mm flatbed is a premier industrial metal working multi-finishing machine. This single belt dry working machine is equipped with a powerful motor, allowing it to process the toughest and heaviest jobs around.

- Stock No

- PD1193

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Birkett Cutmaster 901-M1

- Hp/Kw

- 15kW main motor

- Other Info

- Graining de-burring finishing machine.

- Condition

- Good Condition

- Refurbished Price [?]

- £ 6,775 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Grindingmaster Twin Head, Belt and Brush MCSB-B 900mm Wide Belt Sander

This pre owned Ellesco Grindingmaster twin head MCSB 900 is a 900mm wide belt dry working Grindingmaster that is equiped with powerful motors allowing it to process the toughest and heaviest jobs around. The second head is fitted with a brush to clean and polish the components for a superior finish.

- Stock No

- PE1204J

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Grindingmaster MCSB-B-900

- R.P.M.

- Variable

- Hp/Kw

- 15kW & 7.5kW

- Other Info

- Heavy Duty Through Feed Belt Grinder

- Condition

- From a working environment, Good Condition

- Refurbished Price [?]

- £ 9,750 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Ellesco Grindingmaster 3000

This pre-owned Ellesco Grindingmaster is a premium industrial metal working multi-finishing machine, featuring a GR-3200-600mm wide belt. This has a powerful motor allowing it to process the toughest and heaviest jobs around, suitable for high levels of stock removal.

- Stock No

- PE1216

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Ellesco GR-3200-600

- Year of Manufacture

- 1996

- Hp/Kw

- Twin Belt Linish Head each 40Hp / 30Kw

- Other Info

- Very Heavy Duty Floating Workbed Machine

- Condition

- From a working environment, Excellent Condition

- Location

- Arriving in our warehouse soon

- Price

- Please call on +44 (0) 1922 45 8000

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now