What is the Difference Between an Industrial Oven and An Industrial Furnace?

Although industrial ovens and furnaces are both fireproof boxes that perform heat treatment processes, they have many differences and functions that are important to distinguish, such as their temperature, heat distribution, and design.

Temperature: One of the biggest differences between an oven and a furnace is their temperature. The maximum operating temperature for an oven is up to 750°C and a furnace heats above 535°C and can rise up to 3,000°C.

Heat Distribution

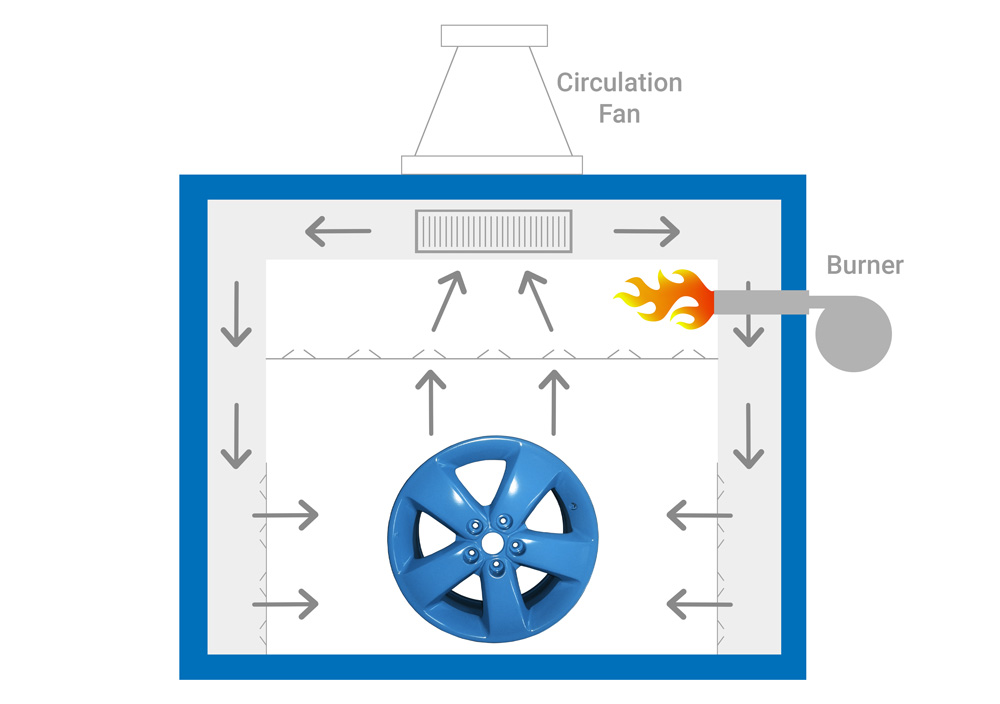

Industrial Ovens: In ovens, the air is released into a separate heating chamber, which contains a recirculation fan and the heat source, such as a gas burner or electric heating element.

The amount of recirculated air required is high in order to transfer the heat successfully from the source to the parts under heat treatment.

Example of gas-fired oven

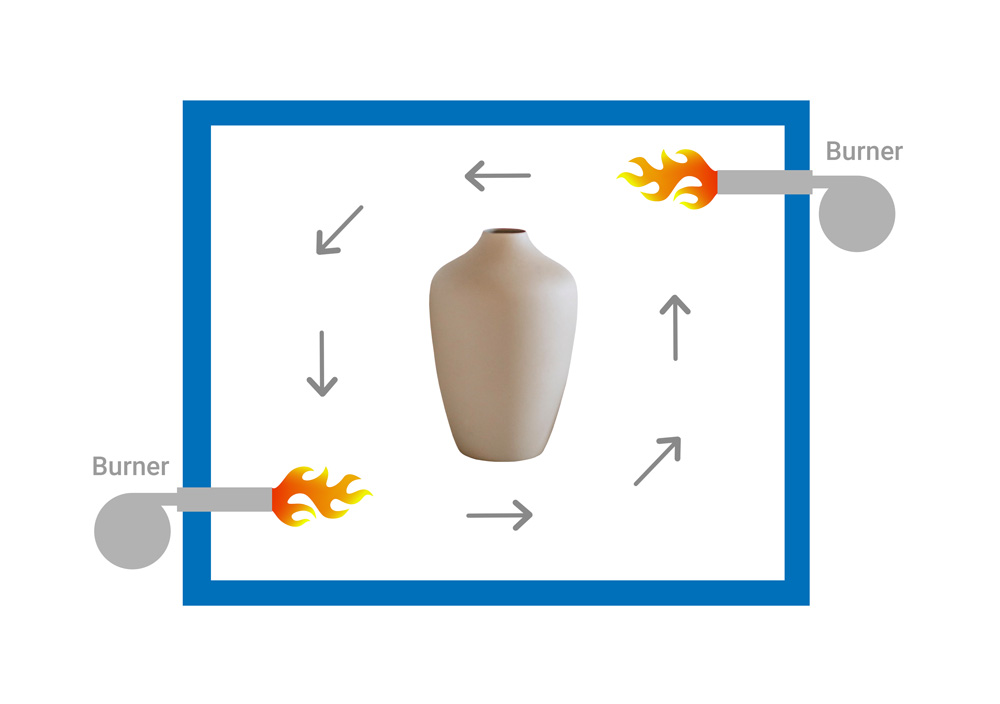

Industrial Furnaces: The heat is introduced directly to the parts under heat treatment. Depending on the heat source of a furnace, the heat source can be placed in various configurations in order to provide the most uniform heating.

In gas-fired furnaces, burners fire above and below the load, which is elevated on high-temperature structural members called piers or furniture. In gas-fired furnaces, the combustion fans are interlocked with the control system so the gas is shut off if they fail.

In electric-heated furnaces, heating elements are mounted directly into the interior sidewalls and radiate heat onto the load.

The heat flow of a furnace

Oven Design

Ovens utilise a sheet-metal interior and exterior that is 18 or 20 gauge. Its insulation consists of a mineral-wool stye that is 75mm at lower temperatures and 100mm thick at temperatures above 260°C. In any industrial oven, the air needs to flow successfully from the air supply duct to the return duct.

Furnace Design

Industrial furnaces are made up of a heavy steel plate exterior of 5-13 mm thickness, and its insulation is 200-300mm thick and either ceramic modules, ceramic blankets, or refractory brick. The thicker the steel exterior shell is, the greater it will help maintain flatness and prevent buckling due to higher temperatures.

Types of Ovens

- Industrial Electric Oven: Oven that uses electricity and has quick heat-up times, and precision temperature controls. They are good for dealing with combustible products or working with metals like aluminium.

- Direct Gas Oven: Heats up quicker and maintains temperature longer than an electric or infrared oven. Direct gas ovens have many functions, among them are curing coatings on steel and assisting in the production of automotive parts such as brake pads and linings.

- Curing ovens: Cause powder or paint to bond with metals, and they harden products from rubber, plastics and various metals. Curing ovens are powered by electricity, UV rays, hot oil, steam or natural gas.

- Drying Ovens: Remove moisture, heat treat metal for the extrusion process and sterilize medical equipment.

- Batch Ovens: Heat large quantities of products and come in a variety of sizes and shapes.

Types of Furnaces

- Gas and Oil Furnaces: These types of furnaces burn gas or oil to generate heat. When gas or fuel burns, the furnace generates hot gas which is required to heat the room or the metals.

- Electric Furnaces: Furnaces that convert electricity to heat- they generate heat through heating elements that are made up of wound coils of resistive wire for mid-temperature range, and silicon carbide and molybdenum disilicide for higher temperatures.

- Kilns: These types of furnaces are used in pottery and ceramic application. They can either be fueled by natural gas or electricity and are typically used for drying, hardening clay and glazes.

Applications

Both industrial ovens and furnaces provide great results in their respective applications and temperature ranges. Due to the greater amount of air being circulated, industrial ovens perform better at lower temperatures. The curing of paint and powder, plastic annealing, aluminium ageing, composite curing, calcination, removing moisture, and adhesive drying are some of the applications of ovens.

Industrial furnaces are used for more robust materials such as metals, and processes such as annealing, tempering, hot pressing, preheating, normalizing of forgings, castings, and carburizing.

Ovens and Furnaces for Sale

At Riley´s we have many ovens and furnaces available for sale. These are usually from stock in our large UK warehouse, but sometimes are available direct from the factory they were being used in.

SNOL 350°C Industrial Oven Range

350°C general purpose batch ovens, ideal for a vast range of low temperature thermal processes such as drying, curing and pre-heating.

- Stock No

- NEW070

- Category

- Industrial Ovens

- Model

- SNOL

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 350°C

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

SNOL 650°C High Temperature Oven Range

General purpose high temperature, industrial, batch ovens which set the standard for a wide range of industrial processing applications

- Stock No

- NEW071

- Category

- Industrial Ovens

- Model

- SNOL

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 650°C

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

SNOL 650°C High Temperature Oven with Powered Door

General purpose high temperature, industrial, batch oven suitable for a wide range of industrial processing applications. Includes a vertical powered door.

- Stock No

- NEW072

- Category

- Industrial Ovens

- Model

- SNOL

- Internal Size (WxDxH mm) [?]

- 600 x 750 x 900

- Max Temp

- 650°C

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

SNOL 1200°C - 1300°C Industrial Chamber Furnace Range

SNOL's industrial range of chamber furnaces furnace, is suitable for applications in scientific laboratories, medicine and industrial settings, especially for high temperature processes such as hardening, normalising & stress relieving.

- Stock No

- NEW077

- Category

- Industrial Furnaces

- Model

- SNOL SNOL 1200/1300

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 1200°C - 1300°C

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

SNOL 650°C Vertical Forced Circulation Furnace

A Vertical Forced Circulation Furnace is an industrial oven designed for precise and uniform heat treatment of components, often used for a wide range of heat treatment processes such as tempering annealing and normalising. These furnaces are available in a range of sizes and temperatures up to 650°C

- Stock No

- NEW078

- Category

- Industrial Furnaces

- Model

- SNOL 35/650

- Internal Size (WxDxH mm) [?]

- 300mm Ø x 500mm high

- Max Temp

- 650°C

- Other Info

- 35 litre capacity / 8 kW heater elements

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

SNOL Custom Build Furnaces & Ovens

Custom built ovens and furnaces to meet your project requirements and standards.

- Stock No

- NEW079

- Category

- Industrial Ovens

- Model

- SNOL

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Romer 200°C Industrial Oven Range

200°C general purpose, electric, batch ovens from 3.4m3 upwards. Ideal for a vast range of low temperature thermal processes such as drying, curing and pre-heating.

- Stock No

- NEW080

- Category

- Industrial Ovens

- Model

- Romer

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 200°C

- Other Info

- Touchscreen Control plus iCure Software

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Romer 200°C Convection Industrial Oven Range

200°C electric, batch ovens from 3.4m3 upwards. Without a fan' these ovens are a very cost effective option or ideal for delicate processes that cannot tolerate air movement.

- Stock No

- NEW081

- Category

- Industrial Ovens

- Model

- Romer

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 200°C

- Other Info

- Radiant heating

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Romer Essential Electric Oven Range

200°C general purpose, electric, industrial ovens from 3.4m3 upwards. Ideal for a vast range of low temperature thermal processes such as drying, curing and pre-heating. The Essential range is a cost effective solution where temperature recording is not required.

- Stock No

- NEW082

- Category

- Industrial Ovens

- Model

- Romer

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 200°C

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Romer 300°C Industrial Oven Range

350°C general purpose, electric, batch ovens from 0.9m3 to 8.4m3 in size. Ideal for low to medium temperature thermal processes such as drying, curing and pre-heating.

- Stock No

- NEW083

- Category

- Industrial Ovens

- Model

- Romer

- Year of Manufacture

- Brand New

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 300°C

- Other Info

- Touchscreen Control plus iCure Software

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Romer 600°C Industrial Oven Range

600°C general purpose, electric, batch ovens from 0.9m3. Ideal for range of medium to high temperature thermal processes. Ideal for tempering, glass annealing, drying, preheating, and stress relieving of various materials.

- Stock No

- NEW084

- Category

- Industrial Ovens

- Model

- Romer

- Year of Manufacture

- Brand New

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 600°C

- Other Info

- Touchscreen Control plus iCure Software

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Romer Custom Built Industrial Ovens

Romer and RSW are working together to offer custom built ovens manufactured to your requirements and specifications. The perfect solution if you know what you need and cannot get it as a standard oven. High quality build standards and low prices define a very competitive package.

- Stock No

- NEW085

- Category

- Industrial Ovens

- Model

- Romer Various

- Year of Manufacture

- 2023

- Internal Size (WxDxH mm) [?]

- Various

- Other Info

- Custom Ovens For customer requirements.

- Condition

- Brand New, Unused, Current Model

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Romer 250°C Industrial Oven Range

250°C general purpose, electric, batch ovens from 3.4m3 upwards. Ideal for a vast range of low temperature thermal processes such as drying, curing and pre-heating.

- Stock No

- NEW086

- Category

- Industrial Ovens

- Model

- Romer

- Year of Manufacture

- Brand New

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 250°C

- Other Info

- Touchscreen Control plus iCure Software

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Romer 350°C Industrial Oven Range

350°C general purpose, electric, batch ovens from 0.9m3 to 8.4m3 in size. Ideal for low to medium temperature thermal processes such as drying, curing and pre-heating.

- Stock No

- NEW087

- Category

- Industrial Ovens

- Model

- Romer

- Year of Manufacture

- Brand New

- Internal Size (WxDxH mm) [?]

- Various

- Max Temp

- 350°C

- Other Info

- Touchscreen Control plus iCure Software

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Efco Top Loading Roller Lid Electric Drying and Treatments Oven

Efco Top Loading Well Type Roller Lid Electric Drying and Treatments Oven

- Stock No

- OA2172

- Category

- Industrial Ovens

- Model

- Efco Well Type Drying and Treatments Oven

- Year of Manufacture

- 08.1999

- Internal Size (WxDxH mm) [?]

- 1800 x 1800 x 2000

- Max Temp

- 150°C

- Other Info

- High 36kw rating

- Condition

- Seen working by RSW, Excellent Condition

- Location

- Rolls Royce stores, near Derby, UK

- Sold As Seen Price [?]

- £ 4,750 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now