The Method of Vibratory Finishing

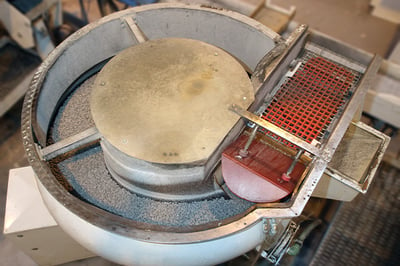

In vibratory finishing equipment, materials go into a bowl or tub, and the entire load shakes all at once. This movement causes the media to rotate or move up and down within a tub. The parts and media rub against each other to achieve the surface finishing objective. The friction in a vibratory system occurs with every pulse of vibration. Vibratory finishing works best for large and small parts in order to create a smoother finish.

What is a Vibratory Machine?

A vibratory tumbler, trough or bowl is the equipment used in a vibratory finishing process and is one of the most common methods in mass finishing. This finishing process is to clean, deburr, descale and polish workpieces. It can also be used as a surface preparation step to enhance the bonding of coating, plating, and adhesive materials to the workpiece. The process of a vibratory tumbler involves placing workpieces and parts inside a tub filled with shaped pellets of media and then applying a vibration force to all the tub´s contents. Sufficient vibration force is applied by the motor. During the process, a finishing chemical can be added to the tub.

The machine vibrates and rotates causing the media to rub against metal parts. The friction from the media and metals removes imperfections, scales or rust, and polishes the metal. The barrel grinds with greater force than a vibratory finishing machine. In Barrel tumblers, the deburring only happens in the slide area of the barrel.

Types of Finishing Media

Media is the hard ingredient added into the tumbler to prevent parts from just banging together. Different media has different properties.

- Steel Media: heavy deburring, shining, polishing, and burnishing metal, plastic, or ceramic parts.

- Plastic Media: great at finishing delicate parts in a process that does not involve excess wearing of work parts. Used for general metal deburring, precision deburring, polishing and burnishing. This type of media is used on softer metals such as aluminium or brass and on threaded parts.

- Ceramic Media: used for heavy, light and when fast deburring is needed. This type of media is good for heavy, and hard metals such as steel, and to remove rust on parts. Also used for general purpose polishing. Plastic, steel, stainless steel and aluminium parts are often polished using ceramic media.

- Organic Media: walnut shells can be used for medium to light deburring and for light finishing and polishing. Corn cob is used when finishing some metal parts because of its ability to absorb surface oils on the parts. Organic media is the natural, and safer way for the environment as they are biodegradable, durable and reusable.

Size and Shape of Media

From cylinders and balls to pyramids and sharp-edged stars, finishing media comes in many varieties. The shape of the parts being finished will determine the shape and size needed for finishing media.

- Round, oval and cylindrical: preferred for general use, and have lower chipping rates.

- Triangles, arrowheads and Tri-Star shapes: great for finishing complex parts with hard-to-reach sections. They also have a higher wear rate and are more susceptible to chipping.

- Small media: has more contact with the component surface area than larger materials and produces a smoother, more attractive surface. Production times are longer for small media polishing.

- Large media: Lends itself to aggressive grinding. Provides rapid removal of burs and is also effective for sharp edges.

Types of Vibratory Finishing Equipment

- Vibratory Circular Bowls: Designed to process small to medium sized components

- Vibratory Troughs: Designed to process long and delicate components

- Maize Dryers: Excellent drying abilities and heating system

- Centrifugal Disc Finishers: Designed to aggressively process small robust components, it has a short process time of deburring polishing of small and medium work pieces.

- Centrifugal Dryers: Drying metal and plastic arts by centrifugal force & hot air

- Floor Separation Units: Floor mounted vibration decks with interchangeable screens

- Bench Top Vibratory Bowls: Suitable for processing small batches

Benefits of Vibratory Finishing

- Vibratory systems produce a smoother finish as their action is more like filing and they do it more quickly.

- A vibratory finishing machine can cut inside a metal part and reach every area the selected media can get into.

- The system can be automatic as they are better for big and delicate parts; this reduces labour costs

- A better option for finishing very large or delicate parts.

- Produce finer results with less wear on parts.

- Increases durability and lifespan of the part.

Rileys Vibratory Equipment

At Riley Surface World, we have a variety of vibratory bowls, maize dryers, floor separation unites, and bench top vibratory bowls to suit your needs; the variety allows you to choose from smaller to larger components and low to high volume of batches.

Walther Trowal Magnetic Conveyor / Seperator

If your work pieces and abrasive media are roughly similar in size, then the external magnetic separation units from Trowal could be the ideal solution for precisely separating parts. This saves both time and money over manually screening your parts and media once it has left the system.

- Stock No

- MB770

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal Electro - Magnetic separator MS225 BL3400

- Year of Manufacture

- 1995

- Capacity

- Track 200mm wide

- Type

- Electro-magnetic mag and de-mag

- Other Info

- Height adjustable between 1300 and 1500m

- Condition

- Seen working by RSW, Good Condition

- Refurbished Price [?]

- £ 1,750 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Rosler R 180/530 Vibratory Finishing Sub Cells - 3 Cells of 3 Available

Three Rosler R180/530 vibratory finishing sub cells (each featuring 3 vibratory troughs) are currently used for medical implant finishing, suitable for many types of small part finishing to a high standard. Each sub-cell is currently for course finishing, fine finishing or polishing.

- Stock No

- TEC475

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Rosler R 180/530 Vibratory Finishing Sub Cells

- Year of Manufacture

- 2016

- Capacity

- 10 Litres/ trough, 30 per cell, 90 Total

- Type

- Course Finish, Fine Finish and Polish

- Other Info

- 11kW, 400V 50 Hz

- Condition

- Seen working by RSW, Good Condition, Current Model

- Location

- Sheffield, UK

- Price [?]

- Please call on +44 (0) 1922 45 8000

- Part of a Direct Site Clearance

- Tecomet Medical Industry Vibratory & Electropolishing Finishing Lines

Rosler R 180/530 Vibratory Finishing Cell

Rosler R180/530 Vibratory Finishing Cell, currently used for medical implant finishing, but suitable for many types of small part finishing to a high standard. Includes waste water treatment, metering and dosing and sludge treatment. Currently set up for three stage finishing and polishing, 3 machines set for each stage.

- Stock No

- TEC500

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Rosler R 180/530 Vibratory Finishing Cell

- Year of Manufacture

- 2016

- Capacity

- Total 60 Litres Max, throughput 65kg

- Type

- Course Finish, Fine Finish and Polish

- Other Info

- 11kW, 400V 50 Hz

- Condition

- Seen working by RSW, Good Condition, Current Model

- Location

- Sheffield, UK

- Price [?]

- Please call on +44 (0) 1922 45 8000

- Part of a Direct Site Clearance

- Tecomet Medical Industry Vibratory & Electropolishing Finishing Lines

Walther Trowal Complete Mass Finishing Vibratory Start to Finish Processing Cell

A Walther Trowal, four stage finishing process comprising of a loading tipper, vibratory finishing bowl, magnetic transfer conveyor and rotating continuous parts dryer.

- Stock No

- VA2172

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal CD600 PN + Load Unload and Dry

- Year of Manufacture

- 1995

- Capacity

- 600L

- Type

- Continuous Automatic

- Other Info

- Load, Wet Process, Separate, Through Dry

- Location

- Rolls Royce Stores Unit 6

- Sold As Seen Price [?]

- £ 8,500 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Walther Trowal CA650 Vibratory Bowl

A Walther Trowal, three stage mass finishing cell / process comprising of a loading tipper, large vibratory helical finishing bowl and rotating continuous 3000Kg's/ Hr continuous parts rotary dryer. Electrical control panel included

- Stock No

- VA2173

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal CA650

- Year of Manufacture

- 1978

- Capacity

- 650Litre

- Type

- Vibratory Bowl

- Other Info

- High Capacity Continuous Finishing Cell

- Condition

- From a working environment

- Sold As Seen Price [?]

- £ 5,750 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Walther Trowal DLT4 Continuous Rotary Drum High Component Volume Maize Dryer

This second hand Walther Trowal DLT4 parts dryer is for the drying of mass produced parts on a continuous basis. Ideally suited as a secondary process after mass parts finishing in vibratory and high energy systems.

- Stock No

- VA2186J

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal DLT.4SM

- Year of Manufacture

- 1987

- Capacity

- 1,000 (kg/h)

- Type

- Continuous parts dryer

- Other Info

- High throughput machine

- Condition

- From a working environment, Excellent Condition, Current Model

- Location

- Unit 6 Derby

- Refurbished Price [?]

- £ 4,950 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Rollwasch SmartLine Round Bowl Vibratory Machine

The Wheelabrator Vibro RVS-5 vibratory bowl with separation and unload is designed for processing medium size components and higher volume batches, as well as prototypes. Well suited for processing metallic components and additive manufactured 3D printed components alike.

- Stock No

- VB2199

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Rollwasch RVS-5

- Year of Manufacture

- 2017

- Capacity

- 550 Litres gross, 350 Litres net

- Type

- Bowl with separator

- Condition

- Seen working by RSW, Ex demonstration, Current Model

- Sold As Seen Price [?]

- £ 14,950 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Acton Waste Water Sludge Separation / Treatment Facility with Centrifuge.

Designed for vibratory surface finishing machines, this settlement tank with centrifuge recycles the process water through the system filtering out the sediment and impurities, returning the clean water to the process for re-use. Sediment is collected in the centrifuge inner chamber lining which is swapped for cleaning and reduced downtime.

- Stock No

- VB2204

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Acton A 800 Batch Centrifuge

- Year of Manufacture

- 2016

- Capacity

- Tank ~ 280L : Centrifuge ~ 100L

- Type

- High Speed Sludge Centrifugal Separator.

- Other Info

- 280L Stainless Steel Holding Mixing Tank

- Condition

- Good Condition, Seen powered at RSW

- Refurbished Price [?]

- £ 5,500 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Walther Trowal Vibration Trough With Dosing System and Settlement Tank

The Walther Trowal VN 200 large parts trough (or tub) vibrators are used for the finishing of mid to large size parts. Normally the parts to be processed are placed into the tub loose where they can rotate freely within the media mass. Pear-shaped trough size 500mm deep x 460mm bottom rad. x 1050 long (approx.).

- Stock No

- VE2227

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal VN 200

- Year of Manufacture

- 1989

- Capacity

- 200Litres (Internal Length = 1050mm)

- Type

- Trough Type Vibratory Finishing Machine

- Other Info

- Variable Speed Drive and Dosing Unit

- Condition

- From a working environment, Good Condition, Current Model

Rosler Model R580/1200 TE-15 Vibratory Trough

This Rosler Model vibratory trough with a divider can process 2 mediums simultaneously with its dual work areas. Includes a sound reducing hood, dosing unit and external weir filtering system.

- Stock No

- VE2228

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Rosler R 580 / 1200 TE-15

- Year of Manufacture

- 2003

- Capacity

- 580 Litres

- Type

- Trough Vibrator

- Other Info

- Dividing Plate so 2 sections can be made

- Condition

- From a working environment, Good Condition, Current Model

Walther Trowal CA340 Vibratory Bowl

The CA340 is a cast poly lined 350 ltr capacity overlapping helical vibratory bowl. The "Circlon" CA bowl is an automatic vibratory process, and with its spiral process channel design which minimises damage and scratches to the components

- Stock No

- VW1159

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal CA 340A

- Year of Manufacture

- OCT/96

- Capacity

- 340 ltr

- Type

- Helical vibratory bowl

- Other Info

- Premier design and build

- Refurbished Price [?]

- £ 4,500 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Abrafin Tornado 30 Litre Bench Bowl Vibrator

Tornado 30 Litre Bench Bowl Vibrator. This 30 Litre bowl utilises lightwork construction to ensure maximum power transfer into useful work. This versatile and flexible machine enables you to cope with a wide range of applications.

- Stock No

- VZ1263

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Abrafin Tornado

- Capacity

- 30 Litres

- Condition

- Seen working by RSW, Seen powered at RSW

- Sold As Seen Price [?]

- £ 2,950 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now