Deburring Machines – What are your Choices?

The formation of burrs not only decreases the quality of metal but also increases its production cost. To remove the burr from edges and holes, deburring is needed. The complexity of the process of deburring depends on various factors including its size, where it is located and the material to be deburred.

Deburring Machinery

Mechanical Deburring Machines

Mechanical deburring machines use brushes, cutters and tools to grind and cut away burrs, especially heavy burrs that are harder for other machinery to deal with. These machines can be manually operated but there are many advanced operations right up to robots with articulated arms.

Well known to Rileys are belt or brush deburring machines. The very basic explanation is that the machine uses “sandpaper” to smooth away the burrs. Naturally, the full explanation is more complicated with machines often using several techniques and abrasives to achieve a great result.

Barrel Tumbling

Barrel tumbling removes burrs and polishes the surface of the metal part. Barrel tumbling can be wet or dry. In wet tumbling, water is loaded, acting as a lubricant and helps wash out residues to improve deburring efficiency. In Dry tumbling, only sand and dried organic materials are used. Sand improves polishing and carries the residues and prevents them from embedding onto the surface of the part.

Vibratory Deburring

Vibratory deburring machines are similar to barrel tumbling where parts are loaded into a chamber along with compounds. The main difference is the movement of the chamber; tumblers rotate to generate agitations inside the chamber, and a vibratory machine vibrates to generate motion.

Water Jet Deburring

In this type of machine, an impact force of high-velocity water jets are used to remove burrs from the metal. Water jets are CNC controlled and low pressure is used to prevent damaging the part so it will only remove thin and loosely attached burrs. The main advantage of waterjet deburring is that it can reach inaccessible areas.

Thermal Deburring

In the thermal deburring process, the metal is exposed to hot corrosive gases for a very short period. A thermal shockwave is generated which quickly vaporizes the burr.

Cryogenic Deburring

This method is applied mostly to precision plastic parts that have inherent impact toughness. Liquid nitrogen is flashed into a chamber containing parts to be deburred. The flashing process cools the chamber near the glass transition temperature of the part material. This process embrittles the burrs and flashes but is not enough to change the properties for the rest of the parts.

Abrasive Blasting

In this process, abrasive media is used to impact the surface and remove any irregularities. Abrasive blasting is used to remove larger burrs and to create the required texture and surface roughness. Micro-abrasive blasting is more precise in creating smoother surfaces without damaging or changing the dimensional accuracy of the part.

Electrochemical Deburring

Electrochemical deburring uses the principles of electrolysis only on the regions where the burrs are located. In this process, an electrolyte is added which transfers charge between the tool and workpiece. This method is used for deburring difficult to machine geometries that are conductive.

At Riley´s we have a variety of machines to suit your deburring needs, such as vibratory bowls, deburring machines, and polishing and belt lining machines

Walther Trowal Magnetic Conveyor / Seperator

If your work pieces and abrasive media are roughly similar in size, then the external magnetic separation units from Trowal could be the ideal solution for precisely separating parts. This saves both time and money over manually screening your parts and media once it has left the system.

- Stock No

- MB770

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal Electro - Magnetic separator MS225 BL3400

- Year of Manufacture

- 1995

- Capacity

- Track 200mm wide

- Type

- Electro-magnetic mag and de-mag

- Other Info

- Height adjustable between 1300 and 1500m

- Condition

- Seen working by RSW, Good Condition

- Refurbished Price [?]

- £ 1,750 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

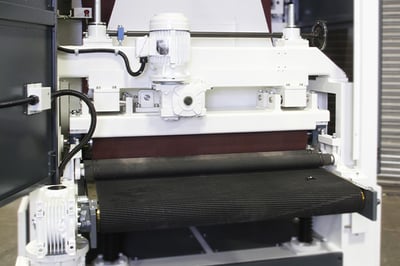

Weber 4 Head Flat Belt Grinder / Sander with Built in Coolant and Filter System

A Weber 4 head flat belt sander with built in coolant and filter system. Two driven grinding/sanding belts plus two driven brushes, with a variable speed work conveying belt and power driven height adjustment.

- Stock No

- PB1156

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Weber NLC-2/2-300

- Year of Manufacture

- 1998

- R.P.M.

- 3000

- Hp/Kw

- 33kW // 44Hp

- Other Info

- Conveyor Belt Width 300mm

- Condition

- Good Condition

Grindingmaster MCSB / B 600

This pre owned Ellesco Grindingmaster is a premier industrial metal working multi finishing 600mm wide belt dry working machine.

- Stock No

- PB1170

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Grindingmaster MCSB / B 600

- Hp/Kw

- 15 // 11

- Other Info

- 600mm wide belt

- Condition

- From a working environment, Seen powered at RSW

- Sold As Seen Price [?]

- £ 6,450 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Lissmac SMD123RE Wide Belt Graining / Counter Rotating 4 Brush Deburring Machine with Wet NonFlam Extractor

The LISSMAC ECOline grinding machine is a versatile machine that is designed to machine sheet materials or components that require either, deburring, edge rounding, surface finishing, or oxide/slag removal following a previous operation or production treatment. Waste dust is controlled by the matched, ESTA wet ATEX collector.

- Stock No

- PC1186J

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Lissmac SMD123RE

- Year of Manufacture

- 2017

- R.P.M.

- Various (see details below)

- Hp/Kw

- Power Input 28.5kVA

- Other Info

- Total Coverage, Belt + Rotating Brushes.

- Condition

- Seen working by RSW, Excellent Condition, Current Model

- Refurbished Price [?]

- £ 45,000 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Birkett Cutmaster Through Feed Horizontal Belt Linishing and Sanding Machine

This Birkett Cutmaster 900mm flatbed is a premier industrial metal working multi-finishing machine. This single belt dry working machine is equipped with a powerful motor, allowing it to process the toughest and heaviest jobs around.

- Stock No

- PD1193

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Birkett Cutmaster 901-M1

- Hp/Kw

- 15kW main motor

- Other Info

- Graining de-burring finishing machine.

- Condition

- Good Condition

- Refurbished Price [?]

- £ 6,775 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Grindingmaster Twin Head, Belt and Brush MCSB-B 900mm Wide Belt Sander

This pre owned Ellesco Grindingmaster twin head MCSB 900 is a 900mm wide belt dry working Grindingmaster that is equiped with powerful motors allowing it to process the toughest and heaviest jobs around. The second head is fitted with a brush to clean and polish the components for a superior finish.

- Stock No

- PE1204J

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Grindingmaster MCSB-B-900

- R.P.M.

- Variable

- Hp/Kw

- 15kW & 7.5kW

- Other Info

- Heavy Duty Through Feed Belt Grinder

- Condition

- From a working environment, Good Condition

- Refurbished Price [?]

- £ 9,750 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Ellesco Grindingmaster 3000

This pre-owned Ellesco Grindingmaster is a premium industrial metal working multi-finishing machine, featuring a GR-3200-600mm wide belt. This has a powerful motor allowing it to process the toughest and heaviest jobs around, suitable for high levels of stock removal.

- Stock No

- PE1216

- Category

- Through feed flat bed Linishing & Brushing Machinery

- Model

- Ellesco GR-3200-600

- Year of Manufacture

- 1996

- Hp/Kw

- Twin Belt Linish Head each 40Hp / 30Kw

- Other Info

- Very Heavy Duty Floating Workbed Machine

- Condition

- From a working environment, Excellent Condition

- Location

- Arriving in our warehouse soon

- Price

- Please call on +44 (0) 1922 45 8000

Rosler R 180/530 Vibratory Finishing Sub Cells - 3 Cells of 3 Available

Three Rosler R180/530 vibratory finishing sub cells (each featuring 3 vibratory troughs) are currently used for medical implant finishing, suitable for many types of small part finishing to a high standard. Each sub-cell is currently for course finishing, fine finishing or polishing.

- Stock No

- TEC475

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Rosler R 180/530 Vibratory Finishing Sub Cells

- Year of Manufacture

- 2016

- Capacity

- 10 Litres/ trough, 30 per cell, 90 Total

- Type

- Course Finish, Fine Finish and Polish

- Other Info

- 11kW, 400V 50 Hz

- Condition

- Seen working by RSW, Good Condition, Current Model

- Location

- Sheffield, UK

- Price [?]

- Please call on +44 (0) 1922 45 8000

- Part of a Direct Site Clearance

- Tecomet Medical Industry Vibratory & Electropolishing Finishing Lines

Rosler R 180/530 Vibratory Finishing Cell

Rosler R180/530 Vibratory Finishing Cell, currently used for medical implant finishing, but suitable for many types of small part finishing to a high standard. Includes waste water treatment, metering and dosing and sludge treatment. Currently set up for three stage finishing and polishing, 3 machines set for each stage.

- Stock No

- TEC500

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Rosler R 180/530 Vibratory Finishing Cell

- Year of Manufacture

- 2016

- Capacity

- Total 60 Litres Max, throughput 65kg

- Type

- Course Finish, Fine Finish and Polish

- Other Info

- 11kW, 400V 50 Hz

- Condition

- Seen working by RSW, Good Condition, Current Model

- Location

- Sheffield, UK

- Price [?]

- Please call on +44 (0) 1922 45 8000

- Part of a Direct Site Clearance

- Tecomet Medical Industry Vibratory & Electropolishing Finishing Lines

Walther Trowal Complete Mass Finishing Vibratory Start to Finish Processing Cell

A Walther Trowal, four stage finishing process comprising of a loading tipper, vibratory finishing bowl, magnetic transfer conveyor and rotating continuous parts dryer.

- Stock No

- VA2172

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal CD600 PN + Load Unload and Dry

- Year of Manufacture

- 1995

- Capacity

- 600L

- Type

- Continuous Automatic

- Other Info

- Load, Wet Process, Separate, Through Dry

- Location

- Rolls Royce Stores Unit 6

- Sold As Seen Price [?]

- £ 8,500 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Walther Trowal CA650 Vibratory Bowl

A Walther Trowal, three stage mass finishing cell / process comprising of a loading tipper, large vibratory helical finishing bowl and rotating continuous 3000Kg's/ Hr continuous parts rotary dryer. Electrical control panel included

- Stock No

- VA2173

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal CA650

- Year of Manufacture

- 1978

- Capacity

- 650Litre

- Type

- Vibratory Bowl

- Other Info

- High Capacity Continuous Finishing Cell

- Condition

- From a working environment

- Sold As Seen Price [?]

- £ 5,750 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Walther Trowal DLT4 Continuous Rotary Drum High Component Volume Maize Dryer

This second hand Walther Trowal DLT4 parts dryer is for the drying of mass produced parts on a continuous basis. Ideally suited as a secondary process after mass parts finishing in vibratory and high energy systems.

- Stock No

- VA2186J

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Walther Trowal DLT.4SM

- Year of Manufacture

- 1987

- Capacity

- 1,000 (kg/h)

- Type

- Continuous parts dryer

- Other Info

- High throughput machine

- Condition

- From a working environment, Excellent Condition, Current Model

- Location

- Unit 6 Derby

- Refurbished Price [?]

- £ 4,950 (+ VAT)

- Special Price (refurbished) [?]

- Login or Register for price.

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Cruickshank Barrel Type Motorized Deburring / Cleaning Machine

Open ended, medium duty, tilting tumble barrel for use with a variety of components for cleaning and deburring.

- Stock No

- VA221

- Category

- Barreling & Rumbling Machinery

- Model

- Cruickshank Medium duty barrel

- Capacity

- 255 dia x 350

- Type

- Open Ended Barreling / Rumbling Machine

- Other Info

- Upgraded Electrical Controls

- Condition

- Seen working by RSW, Good Condition

- Sold As Seen Price [?]

- £ 1,250 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Cruickshank Barrel Type Motorized Deburring Machine

Open ended, medium duty, tilting tumble barrel for use with a variety of components for cleaning and deburring.

- Stock No

- VA222

- Category

- Barreling & Rumbling Machinery

- Model

- Cruickshank Medium duty barrel

- Capacity

- 335 dia x 490

- Type

- Open Ended Barreling / Rumbling Machine

- Other Info

- 1425/31 rpm

- Sold As Seen Price [?]

- £ 950 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Rollwasch SmartLine Round Bowl Vibratory Machine

The Wheelabrator Vibro RVS-5 vibratory bowl with separation and unload is designed for processing medium size components and higher volume batches, as well as prototypes. Well suited for processing metallic components and additive manufactured 3D printed components alike.

- Stock No

- VB2199

- Category

- Vibratory Deburring & Polishing Machines

- Model

- Rollwasch RVS-5

- Year of Manufacture

- 2017

- Capacity

- 550 Litres gross, 350 Litres net

- Type

- Bowl with separator

- Condition

- Seen working by RSW, Ex demonstration, Current Model

- Sold As Seen Price [?]

- £ 14,950 (+ VAT)

- Special Price (sold as seen) [?]

- Login or Register for price.

- Special offer ends

- 05 November 2025 15:00 GMT while stocks last

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now